- Home

- About

-

Services

- Equipment Procurement & Supply Chain Services

- Instrument Calibration Services

- Design, Engineering & Technical Services

- Blasting & Painting Services

- Scaffolding Services

- Cold Cutting

- Bolt Tightening

- Quality Control & Inspection Services

- NDT Services

- Hydro-Jet Cleaning

- Heat Exchanger Retubing

- Chemical Cleaning

- Project Management and Digital Twin Application

- Insulation Services

- Projects

- Contact

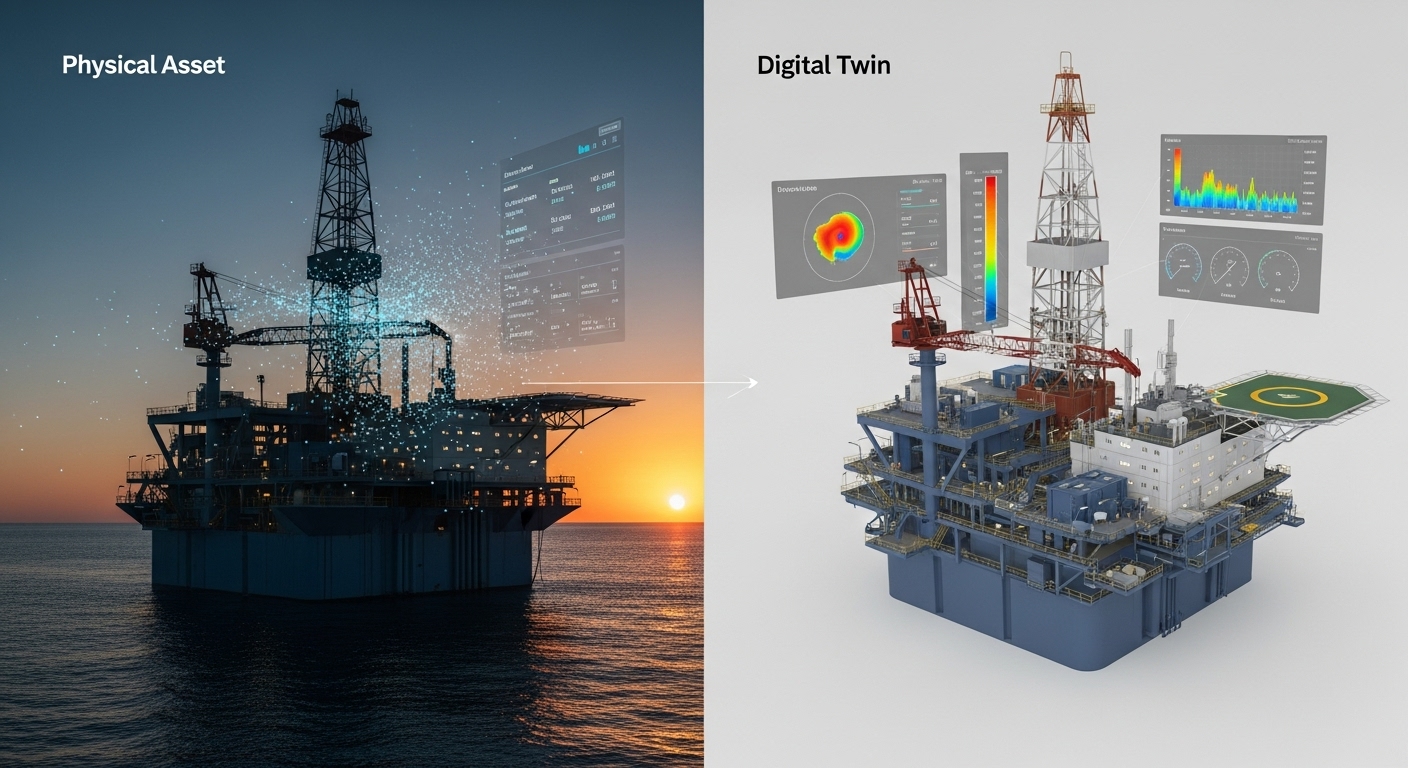

Digital Twin as a Service: De-Risking and Optimizing Your E&P Assets

Enhance production, ensure maximum safety, and advance your sustainability targets with a dynamic, data-driven replica of your physical operations. Our Digital Twin as a Service delivers proven upstream, midstream, and downstream results.

In today’s environment, maximizing asset integrity and operational efficiency is paramount. Our Digital Twin as a Service (DTaaS) provides a comprehensive, managed solution, giving you a real-time window into your assets to drive smarter decision-making, reduce downtime, and lower operating costs.

At LMB5 Solutions, we see Digital Twins as a game-changer in the journey to decarbonize the built environment. Our Performance Digital Twin technology blends physics-based simulation with real-time data to create a living, scalable virtual model, from a single building to an entire campus, city, or portfolio. It mirrors real-world behavior to deliver deep insights into building performance, helping stakeholders make smarter decisions to cut energy use, reduce costs, and move closer to net-zero targets.

Real-time Data Integration

Digital Twins stay continuously in sync with the physical world by pulling in live data from sensors, IoT devices, and other connected systems. This constant flow of information ensures an accurate, up-to-date digital representation of the asset or environment at all times.

Simulation and Modeling

Digital Twins use advanced simulation and modeling techniques to replicate how an asset or system behaves under various conditions. This capability enables predictive analysis, performance optimization, and scenario planning, helping teams anticipate outcomes and make smarter, data-driven decisions.

Engineering to Services

The Digital Twin in Engineering

In engineering, Digital Twin technology enables full system modeling and simulation long before physical production begins. By combining Model-Based Systems Engineering (MBSE) with detailed digital design, it creates a virtual version of the product — allowing engineers to validate requirements, optimize designs, and predict performance in a risk-free digital environment. This proactive approach helps uncover potential issues early, minimizing costly late-stage changes and ensuring every design meets its intended performance standards.